Description

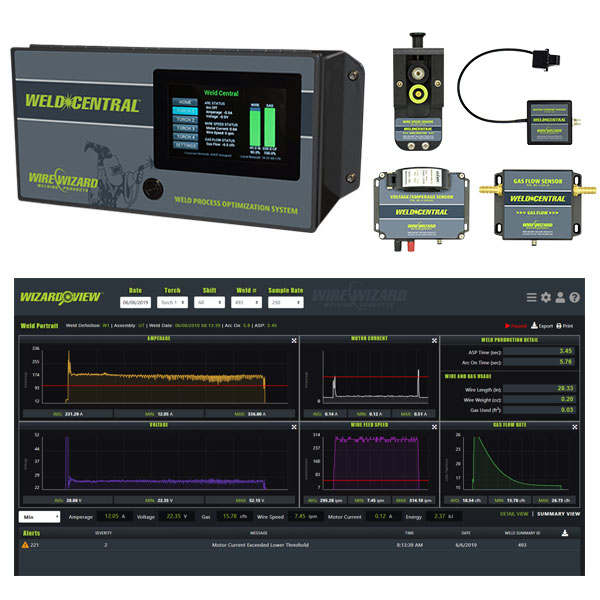

The new Weld Central® is a Process Optimization System that monitors and tracks key (time-stamped) process variables, including current, voltage, wire feed speed, gas flow & feed motor current. This information can be utilized for both process optimization and determining the weld cell OEE (Overall Equipment Effectiveness). Combined with the Wizard View® software, the Weld Central® is the ultimate weld cell performance monitoring system!

Complete system includes:

- Weld Central® Controller

- Two models available – one that can monitor up to 2 torches and one for up to 4 torches

- One Sensor Kit (additional kits sold separately), including:

- Wire Speed Sensor

- Gas Flow Monitor

- Voltage/Amperage Sensor

- Feed Motor Current Sensor

- Wizard View® Software Package (1 license), Standard or Advanced version

Not Included:

- Additional Sensor Kits, if monitoring more than one torch

- Monitor, keyboard/mouse & HDMI cable (required only for initial setup if installed on local network)

Weld Central® & Wizard View® Features:

- Monitor robotic or semi-automatic weld cells through a PC or mobile device using the Wizard View® software, where collected data can be viewed, charted & exported in a user friendly web browser interface

- Each controller can monitor up to four torches with inputs for up to four sets of sensors

- Equipment agnostic — utilizes sensors compatible with all brands of wire feeders and power sources

- Capacitive touchscreen interface displays arc status, wire speed, gas flow and wire/gas remaining

- More than just a data acquisition system — PLC integration through Modbus or Profinet protocol can be utilized to activate an alarm or stop the welding process if welds fall outside of user defined parameters, preventing costly weld quality issues

- Active Inputs for resetting the wire remaining (new wire package) and new gas canister (if applicable)

- Internal memory on controller can store up to 180 days of weld summary data (depending on duty cycle)

- Monitor a single torch or multiple weld cells through a network or mobile router with Wizard View™ software

- Gas flow sensor is pre-calibrated for a variety of gas mixtures, including Argon/CO2 (90/10, 85/15, 80/20, 98/2 or 75/20), Argon/Helium (75/25), Argon O2 (97/3), He/Ar/CO2 (90/7.5/2.5) and 100% Argon, CO2, Helium or Nitrogen

Wizard View® Monitoring and Data Acquisition Software

Wizard View® provides an easy to use interface for the Weld Central® System that graphs and logs data, alerts, wire & gas usage and other key welding performance information. The software collects data from any torch with the Weld Central® hardware installed. Simply browse to the desired torch to see a visual representation of the welding data along with the wire and gas usage information. One software license is included with each Wizard View controller.

- Monitor, graph and export welding data to a CSV file

- Basic and Advanced versions of Wizard View® are available. Choose Wizard View® Basic for monitoring performance on individual torches or weld cells. Wizard View® Advanced features the ability to monitor performance and productivity for an entire facility or assembly line.

- Dashboard displays all welding data in an interactive chart and shows overview of the total number of welds, wire usage, gas usage, power usage & arc on time for a selected time frame

- Track and compare welding performance data to test and verify process improvements

- Data may be displayed for each assembly and by weld I.D.

- Integrated ROI Calculator provides a quick and easy way of calculating cost savings after making process improvements

- Logs and displays user defined alerts so problems can quickly be detected and resolved

- Provides much of the data necessary to determine weld cell OEE (overall equipment effectiveness)

Wizard View® Weld Summary Screen

ORDERING & CUSTOMER SERVICE:

ORDERING & CUSTOMER SERVICE: